For installation details please download the fitting instructions above, or see your local distributor for further measure and installation details.

If installing on plaster or wallboard where possible pick up timber stud. If unable to locate stud, use a suitable wall plug or toggle for plasterboard to hold the brackets.

Face / Architrave Fit:

Spring Operated – the top edge of the brackets should be 35mm above the opening. Spring spade is always located on

the left side for under roll and on the right for over roll blinds.

Check your blinds pin measurement. This is the measurement from the end of the blind to the

other, taken from the outside of the end pins. Position the brackets in the correct position:

Chain Operated – the top edge of the brackets should be flush with the top of the architrave.

Avoid affixing screws into the angle join of the architrave. Raise or lower the brackets if necessary to avoid this.

Recess Fitting:

Side or Back fixing

Position the bracket so that the top edge is a half roll diameter down from the top of the recess.

Check the pin measure of the blind. This is the measurement from the end of the blind to the other,

taken from the outside of the end pins. Transfer this measurement to the window to determine whether the brackets

should be top, side or back mounted.

Top fixing

The brackets should be installed with the slotted screw holes nearest to the window. The edge of the

brackets that are nearest to the window should be a half a roll diameter less 15mm from the back of the recess.

Mark through the elongated screw holes of the bracket and drill using a 2.5mm drill for the timber fixing, or an

appropriate size masonry drill if plug fixing. Screws must be at least 25mm from the edge of masonry to avoid splitting.

Secure the brackets into position – each one with one screw only, through the slotted holes to allow for adjustments.

When satisfied with the position, drill through the round holes and secure with additional screws.

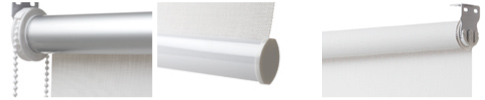

Mount blind to brackets:

Spring Operated

Fit pin into its bracket first (right for standard roll, left for reverse roll). Fit spade end into its bracket.

Chain Operated

Fit the chain control end into the bracket with the ‘spade’. Whilst holding the blind with one hand, turn

the idle end until the pin withdraws into the roller cavity. Align this end with the bracket and turn the idle end again until

the pin re-emerges and fits into the bracket. Install cord tension device. Snap on Ball Stops to the chain at appropriate

position to keep the blind operating within its limits. Ball Stops prevent over unwinding of fabric that, in extreme cases,

may cause the fabric to come off the roller.

Rolling up straight - How to balance the blind

For blinds that are narrow with long drops; with ratios more than 1:2.5 (width: drop), there is a tendency for the blind to

roll to one side. Frequently, windows can be out of square; therefore, final on-site adjustment may be required even

though the blind has been carefully balanced at the factory. The way to re-balance - Locate the end with the overlapping

edge exposed. Roll down the blind and apply a piece of masking tape on to the aluminium tube at this end. Roll up the

blind and check that the blind is now rolling up straight. More tape can be added or removed to ‘fine tune’ the balance.

Note: Fine tuning should NOT require more than 3 full pieces – please ring Contract Blinds for further advice.

How to install the Cord Tension device

The Tension Device reduces the chance of strangulation by limiting access to the control cord or chain. When fitted

properly it should hold any looped controls firmly tensioned against a wall or window frame. This should make it hard for a

young child to fit though the controls.

Clip the cord / chain through the bottom of the Tension Device. Position the Tension Device on the window frame or wall

in a position that will not compromise the operation of the control cord / chain. Make sure the controls are not twisted

when the Tension Device is in the mounting position. Ensure that there is SUFFICIENT TENSION on the chain/cord –

however excessive tension will impair smooth operation of the blind. Hold the Tension Device in the correct position, as

shown. Insert and secure the screw through hole. Make sure the screw is affixed into a solid surface.